Introduction of Thermal Insulation Jacket for Plate Heat Exchanger

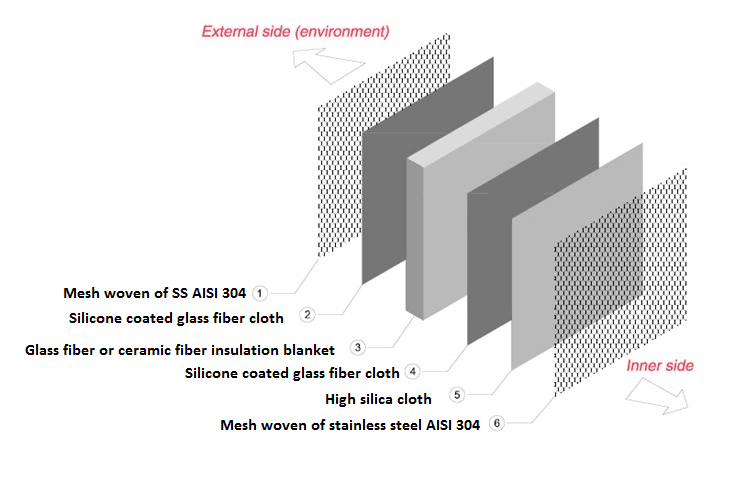

Thermal Insulation Jackets for Plate Heat Exchanger have three to six layers, liner is high silica glass fiber cloth, stainless steel braided cloth, ceramic fiber cloth, glass fiber cloth or high-SI aluminum cloth, and insulating layer is ceramic or glass fiber or aero gel blanket, and the protection layer is silicone coated glass fiber cloth, teflon cloth or stainless steel braided cloth, which is water, oil, acid and alkali proof. The thickness is 5-150 mm, which could be customized, temperature resistance could be as high as 1000 cent degree. Normal lifetime is more than 5 years. And the energy saving rate is 25% to 40%.

Types of Thermal Insulation Jacket for Plate Heat Exchanger

A) Cold insulation type

B) Low temperature insulation type (below 300℃);

C) Standard type (300—600℃).

D) High temperature insulation type (above 600 C).

Features of Thermal Insulation Jacket for Plate Heat Exchanger

- Thermal conductivity: 0.035 W/M•K- 0.045 W/M•K±0.005 (Normal temperature)

- Temperature tolerance: high temperature tolerance: 1000-280℃, low temperature tolerance 70℃

- Inflaming retarding: non flammable (Fireproof A class, GB8624-2006, German standard DIN4102, A1 class)

- Density: 110-220Kg/m

- Thickness: 5-150MM

- Moisture absorption rate:<5%

Application of Thermal Insulation Jacket for Plate Heat Exchanger

- Barrel heater on injection molding machine, extruder etc.

- Molds and dies

- Flange, Pipe, Valve

- Exhaust Elbow

- Heater exchanger

- Exhaust pipe of engine

- Any other applications needed to reduce heat loss

- Minimize heat loss by 20%-40%

- The surface temperature can be lowered to 40℃, and thus safe to touch by hands

- We support customized design to ensure 100% fit your application

- Easy to install by buckles

- Water and oil proof, multi-layer protection, anti-corrosion, easy to clean, easy to bend, pollution free and neat out looking.

- Dimension, cut/hole sizes and positions are required for quotation. Drawings and pictures are preferred.

|

|

|

|

|

|

|

|

|

|

Shanghai PAMAENS Technology Co., Ltd located in Shanghai, specialized in researching, developping and manufacturing heaters, plastic machinery accessaries and energy saving products. We have strong researching and developping team, many of our engineers have more than ten years experience on manufacturing heaters, and we have stict quality control system, and a team of professional sales people, so no matter manufacturing process, products quality, or prices, we believe few factories could compare with us in China.

1. Lowest default rate

2. One to two year warranty

3. Best and on time after sale service

4. You are worried, we would like you to think

How to contact with us?

-

Exhaust Insulation Jacket

-

Removable Insulation Jackets

-

Customized Heat Insulation Extruder Jacket Supp...

-

Band Heater Insulation Jackets

-

Barrel Insulation Jacket

-

insulation jackets for valve

-

Drum heater

-

Insulation Blanket for Heaters and Injection Ma...

-

Insulation Jacket for Bolier, Furnace and Tank ...

-

Insulation Jacket for Pipe

-

Insulation Jackets for Manifold

-

Valve Insulation Blanket

-

Manifold Insulation Cover

-

Heating Jackets for Pipes