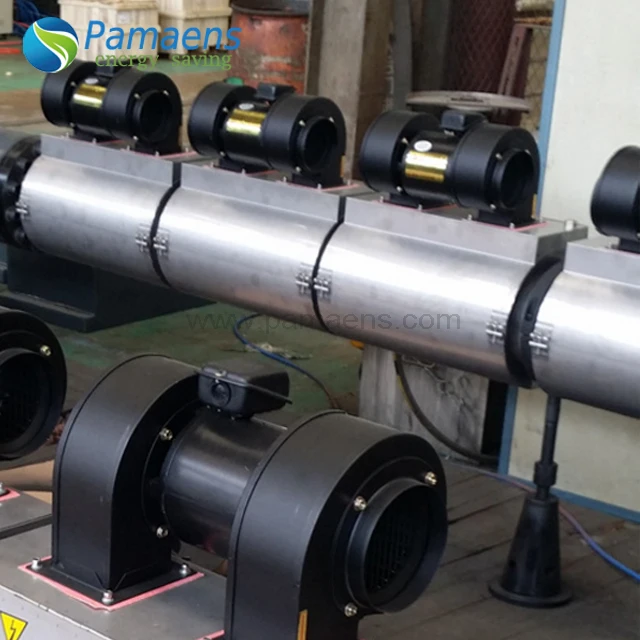

Introduction of Air Cooled Band Heater for Extruder

Heater band is 60% open by perforated metal sheet which ensures maximum surface exposure for better cooling. The heater band is covered with Blower cover for mounting the Blower. Advantages of air cooled over liquid cooled operation includes lower cost, easy replacement, low maintenance, no leakage problem and uniform temperature control.

Additionally, Air Cooled Band Heaters do not require an expensive cooling tower or heat exchange system, extensive plumbing systems and labor for installation. These factors along with the benefit of being maintenance free make PAMAENS’s Air Cooled Band Heaters an economical and practical source for your extrusion heating and cooling application.

Applications of Air Cooled Band Heater for Extruder

(Especially for Products which are sensitive to temperature.)

Plastic Extrusion

Injection Molding

Blow-Molding

Pressure Molding

Structural Foam

Food Industry

Container Pipe and Tank Heating

Packaging

Chemical, Oil & Gas Industries

Types of Air Cooled Band Heater for Extruder

Air cooled ceramic heater

Air cooled mica heater

Air cooled aluminum heater

Air cooled ceramic heater with ceramic fins

Air cooled ceramic heater with copper fins

Air cooled ceramic heater with nickel plated copper fins

Features of Air Cooled Band Heater for Extruder

These Fins are available in width of 45mm, 60mm & 75mm.

Aluminium Fins take 25% & Copper fins takes 35% less time to reach set temperature of 350° C than standard Fins.

Aluminium Fins take 30% & Copper fins takes 35% less time for cooling from 350° C to 100° C than standard Fins.

If working temperature requirement is around 300° to 350° C, it is recommended to use Aluminium Fins as it is cost wise economical.

Aluminium & Copper cooling fins have a maximum operating temperature of 450° C.

These fins can also be used in mounting between heaters as cooling fins.

Advantages of Air Cooled Band Heater for Extruder

To heat and cool the barrel

Low Maintenance

Easy Replacement

Improves Quality of finished products

Space Saving

Increases Productivity

Available with Various Diameter, Length, Voltage, Wattage and Configurations.

Perforated heater with fins to provide faster cooling.

Reference pictures of Air Cooled Band Heater for Extruder